Introduction to Cyclic Corrosion Testing

Reporting

In addition to all of the usual test conditions that need to be reported in conventional salt spray tests, CCT test reports should include:

• Ramp time for all transitions in automated cabinet tests

• Loading (i.e., number samples) of all automated cabinets

• Daily range and mean temperature and relative humidity for the laboratory room where “ambient” conditions are maintained in manual tests

Prohesion Cycle

The Prohesion test was developed in England for industrial maintenance coatings applications. Prohesion also has a reputation as a good test for filiform corrosion.

The Prohesion electrolyte solution is much more dilute than traditional salt fog. In addition, the spray atomizing air is not saturated with water.

Exposure conditions include:

Electrolyte Solution

0.05% sodium chloride & 0.35% ammonium sulfate

Solution Acidity

pH between 5.0 and 5.4

The Prohesion exposure cycle is:

1 hour :Salt fog application at 25°C (or ambient)

1 hour: Dry Off at 35°C (Thedry-off is achieved by purging the chamber with fresh air, such that within 3/4-hour all visible droplets are dried off of the specimens.)

Repeat

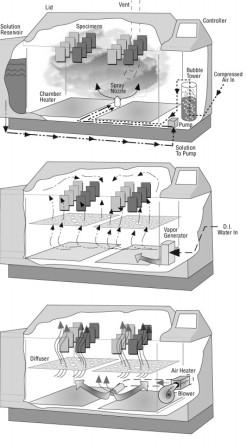

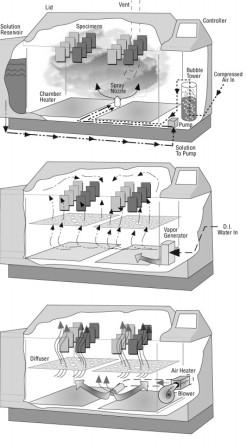

Advantages of Automated CCT

Cyclic corrosion test methods were originally developed as labor intensive manual procedures. Automated, multi-functional chambers are now available and can perform CCT tests in a single chamber. Some of the advantages of automated systems are that they:

• Eliminate manual moving of test specimens from one chamber to another

• Eliminate laborious spraying of test specimens

• Eliminate variability in results from excessive specimen handling

• Allow more predictable transition times

Common Cyclic Corrosion

Test Cycles

The following cycles are in common use. This list is not comprehensive. The conditions shown be- low are merely a summary of the full instructions found in the various specifications, test methods and practices. Consult the actual documents for more complete instructions, warnings, etc.

Other cycles may be more appropriate for your application. SAE J156315 is particularly useful as a source of guidance for cyclic testing.

For industrial maintenance coatings, the addition of UV has been found useful for improving correla- tion on some formulations. This is because UV damage to a coating can make it more vulnerable to corrosion. The Corrosion/Weathering Cycle consists of one week of Prohesion alternating with one week of QUV exposure.

Electrolyte Solution 0.05% sodium chloride& 0.35% ammonium sulfate

Solution Acidity pH between 5.0 and 5.4.

Typical Duration 2,000 hours

Typical Duration 2,000 hours

Corrosion/Weathering Cycle

For industrial maintenance coatings, the addition of UV has been found useful for improving correla- tion on some formulations. This is because UV damage to a coating can make it more vulnerable to corrosion. The Corrosion/Weathering Cycle consists of one week of Prohesion alternating with one week of QUV exposure.

Electrolyte Solution

0.05% sodium chloride& 0.35% ammonium sulfate

Solution Acidity

Solution Acidity

pH between 5.0 and 5.4.

Typical Duration 2,000 hours

The Corrosion/Weathering exposure cycle is:

1 hour Salt fog application at 25°C (or ambient)

1 hour Salt fog application at 25°C (or ambient)

1 hour Dry Off at 35°C

(The dry-off is achieved by purging the chamber with fresh air, such that within 3/4-hour all visible droplets are dried off of the specimens.)

Repeat for one week, then manually move the samples to a QUV Accelerated Weathering Tester and expose at the following cycle:

4 hours UV exposure, UVA-340 lamps, 60°C

4 hours Condensation (pure water), 50°C

Repeat for one week

Manually move the samples to a CCT tester and repeat the whole procedure.